MINAX® 80/3

FOR THE MOST VALUABLE ASSET IN LIFE: OUR SAFETY.

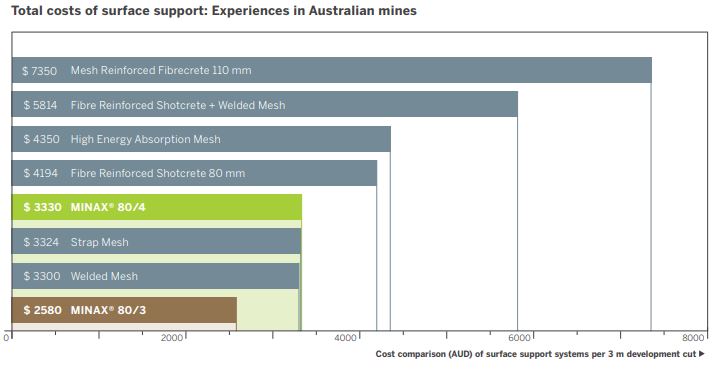

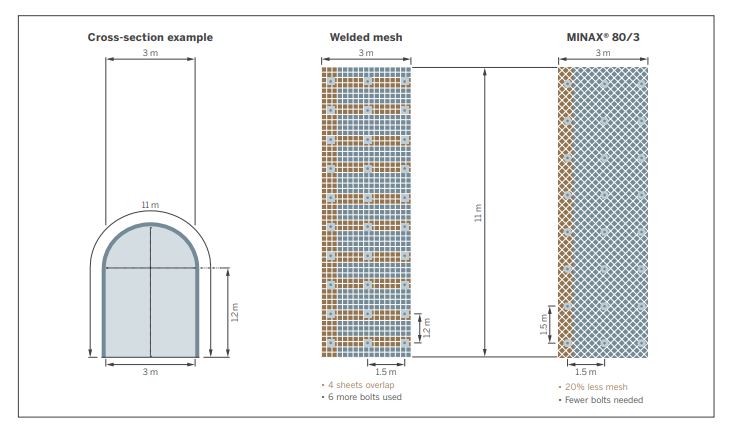

MINAX® 80/3 mesh is for the miners an alternative to welded mesh sheets or mild steel chain-link mesh. It provides high strength combined with very low weight, minimum overlap loss and fast installation. Our high-tensile mesh MINAX® 80/3 with chain-link structure for underground applications is particulary quick and easy to install, offering maximum cost efficiency.

Results of quasi-static tests made by the Western Australian School of Mines (WASM):

MINAX® mesh with a wire tensile strength of 1770 N/mm2 can carry much higher static and dynamic loads than traditional reinforcement nets (graph based on WASM results)

G-Plate®

For optimal load transmission from the rock bolts to the MINAX® mesh. The special spike plate grabs the mesh in 6 positions assuring optimal load transfer, also during blasting works.

T3 connection clips

For a tool-less connection the T3 clip connects the mesh when necessary, ensuring 100% load transfer.

MESHA® installation handler

For a fully mechanized installation of Geobrugg mesh in one working process. The MESHA® can be retrofitted to any development jumbo or bolting machine, without losing a boom for drilling.

QUALITY YOU CAN RELY ON.

Foundation for our solutions is steel wire with a high tensile strength of minimum 1770 N/mm2. Compared to mild steel wire our high-tensile wire offers at least three times higher tensile strength. It is characterized by high mechanical resistance, high energy absorption capability and long life. Designed specifically for the underground mining industry, MINAX® 80/3 offers unparalleled quality through performance, that is synonymous with the Geobrugg name worldwide. We provide MINAX® 80/3 with tailor made corrosion protection solution taking into account your specific mining conditions.

The MINAX® 80/3 mesh provides the following features:

High-tensile steel wire

For high loads: Both static and dynamic capacities (e.g. while blasting) are higher compared to other general surface support materials.

Rhomboidal chain-link structure

For easy handling and storing: The whole installation process becomes much easier.

Low weight

For fast installation: Very light weight relative to its strength due to the high-tensile wire. This makes manual or mechanical installation very easy and improves the occupational health and safety.

Knotted ends

For maximum stability at the edges: Profit from minimized overlapping, optimized number of rock bolts and no sharp edges.

Efficient production

For competitive rates: High-tech production technology allows top quality at a very attractive price. Can be easily provided customized to local needs (bolt spacing and/or advance length)

Cutting edge corrosion protection

Whether hot dip galvanized, ULRACOATING®, SUPERCOATING® or stainless steel: After our analysis of the environmental conditions in your mine, we offer the corrosion protection solution, according exactly to your specific needs.

ALWAYS READY FOR YOUR DEMANDS.

What makes our systems particularly economical, is Geobrugg’s global network – and therefore the local availability of our products. With close proximity to our customers we produce meshes on four continents with precisely controllable state-of-the-art technology. This not only allows top quality at a very attractive price, but also reduces the logistic expenditure, enables short delivery times and provides flexibility to adjust the level of capacity to the customers’ needs.

TECHNICAL DATA: