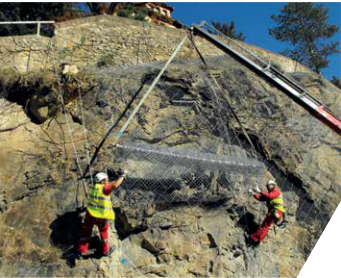

QUAROX® Netting of Rocky Slopes

QUAROX® RCN made from high-tensile steel wire

THE NEW GENERATION OF ROLLED CABLE NETS

QUAROX® Rolled Cable Net allows a form-fit transmission of load and therefore provides unparalleled stability. It differs from conventional rolled cable netting, which is produced using cross clips or binding wires and tends to lose its mesh structure very easily upon localized mechanical stress, such as experienced during rockfall.

QUAROX® REDUCES YOUR INSTALLATION COSTS.

QUAROX® Rolled Cable Net unrolls smoothly and it is possible to cover an area of 117 m² using a single roll. This means QUAROX® can be installed far more efficiently than conventional rolled cable nets, which typically measure 3 x 5 m.

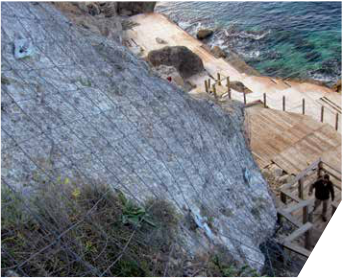

Esthetically superior

Once installed, QUAROX® Rolled Cable Net is almost invisible. Due to its special structure, it does not require the cross clips which are often visible in traditional rolled cable nets

Installation possible using standard mounting components

QUAROX® Rolled Cable Net is installed using conventional support/boundary ropes and shackles. In certain situations, we recommend the use of flexible spiral rope anchors. These are supplied in specific lengths according to project requirements.

QUAROX® PLUS

In order to hold back finer rock material, we deliver QUAROX® Rolled Cable Net on request with a secondary mesh of the same roll size. This can be attached to QUAROX® Rolled Cable Net easily on site if required

QUAROX® is characterized by the following product features:

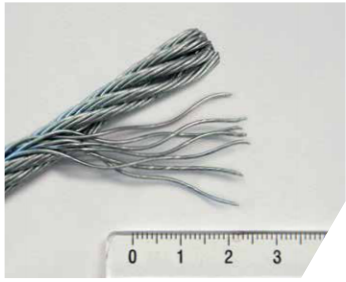

Rolled cable made from high-tensile steel wire:

Benefitting from a wire tensile strength of 1770 N/mm², the rolled cable weighs less and is therefore easier to install. The high shearing resistance of the wire guarantees maximum protection against rock movement.

Knotted ends:

These ensure maximum stability right up to the net edges. The lengths of net can be interconnected without overlapping.

Chain-link structure:

QUAROX® unrolls easily and adapts to uneven terrain to allow a tight fit. Lengths can be shortened simply by unwinding a spiral. Remaining pieces can be used again.

Large surface area per roll:

Each roll covers an area of 3.9 m x 30 m. The long roll length results in fewer interconnections, making installation significantly more efficient.

Cutting edge corrosion protection:

GEOBRUGG SUPERCOATING® lasts for generations. QUAROX® strands are made from 3 mm thick wires, allowing a thicker protection layer to be applied. Corrosion protection is therefore considerably superior to that of conventional rolled cable nets.

ADDED VALUE THAT PAYS OFF: WE DELIVER SAFETY.

Our products are delivered from our worldwide production sites directly to the construction site to ensure the shortest possible delivery times. The delivery process is not only environmentally friendly but also highly efficient for you: we ensure that delivery loads are as compact as possible and packaging is kept to a minimum so that costs are saved.

QUALITY YOU CAN RELY ON.

From storage to truck in one easy operation. Loaded onto special pallets, the rolls have optimal protection during transport, require a minimum of space and are easy to unload.

With its flexible chain-link structure, QUAROX® adapts optimally even to irregular terrain.

Fast installation: QUAROX® is easy to unroll. Because each roll covers an area of 117 m², relatively few anchors are required

Conventional nets are usually delivered in smaller units and therefore require a higher proportion of nails. The larger surface area of the QUAROX® rolls results in an optimized nail pattern which better matches the local geological conditions

QUALITY YOU CAN RELY ON.

The wires of a conventional rolled cable are approx. 0.5 mm thick, meaning only a thin corrosion protection layer can be applied.

meaning only a thin corrosion protection layer can be applied. With conventional rolled cable nets, cross clips often cause the corrosion protection to fail prematurely, primarily as a result of retained moisture and/or the combining of different metals. Moreover, a force-locked cable connection may shift during rockfall, creating a weak point. With strands made of 3 mm thick high-tensile steel wires, QUAROX® allows a significantly thicker corrosion protection layer to be applied and additionally provides an unparalleled shearing resistance

With conventional rolled cable nets, cross clips often cause the corrosion protection to fail prematurely, primarily as a result of retained moisture and/or the combining of different metals. Moreover, a force-locked cable connection may shift during rockfall, creating a weak point.

The form-fit load transmission within a QUAROX® rolled cable net provides optimal stability even under excessive force. Without the visually disturbing cross clips, QUAROX® blends considerably better into the landscape.

ALWAYS AVAILABLE TO MEET ANY DEMAND

One reason our products are so cost-effective is that they are available locally practically worldwide. Our geotechnical products are produced on four continents, which means we are always close to our customers and therefore provide a highly efficient service. Not only do we offer top quality at an attractive price, but we are also able to reduce logistics costs and delivery times. Moreover, our high-tech production can adapt very easily to any order size.

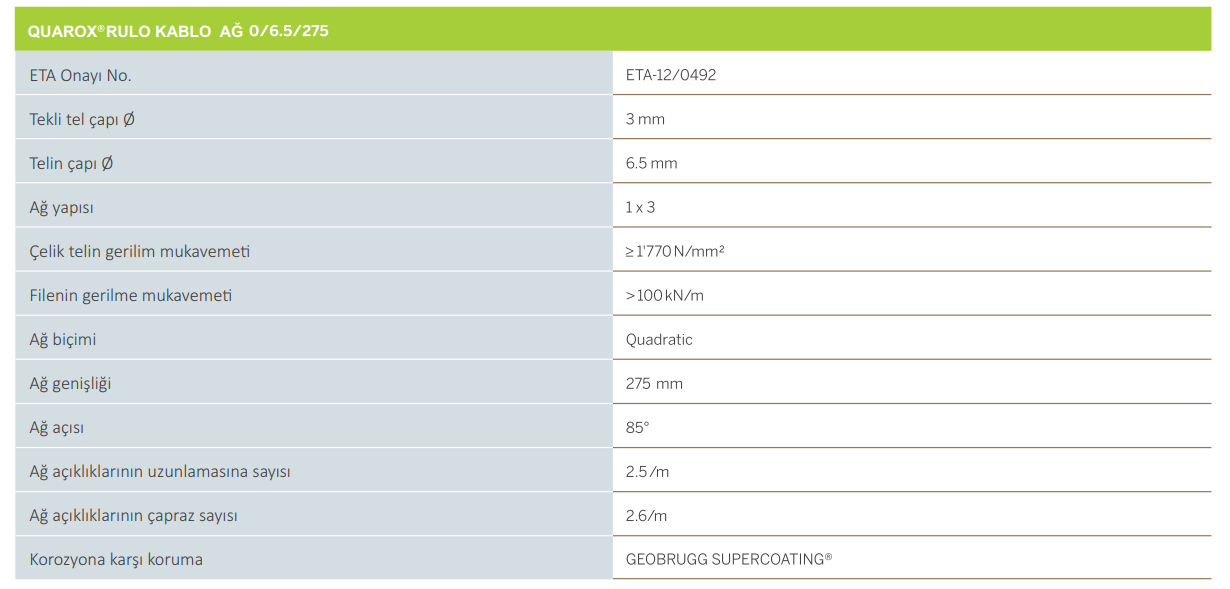

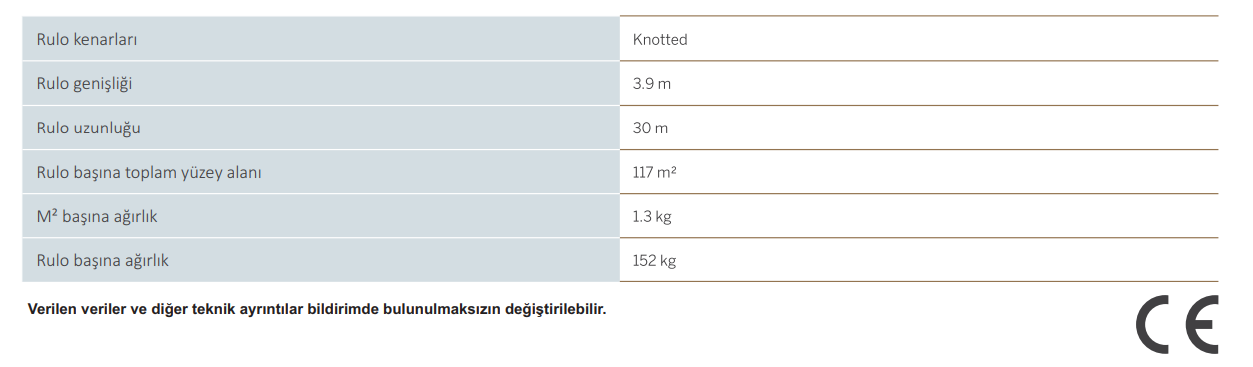

TECHNICAL DATA: